Materyèl

| Kò | Aliminyòm (5050 5052 5056 5154) | (AL Mg 1%-1.5%, 2%-2.5%,3%-3.5%,5%) | ||

| Fini | Poli | Koulè RAL pentire | ||

| Mandrin | Aliminyòm ● | Steel | Asye pur | |

| Fini | Poli ● | Zenk plake | Poli | |

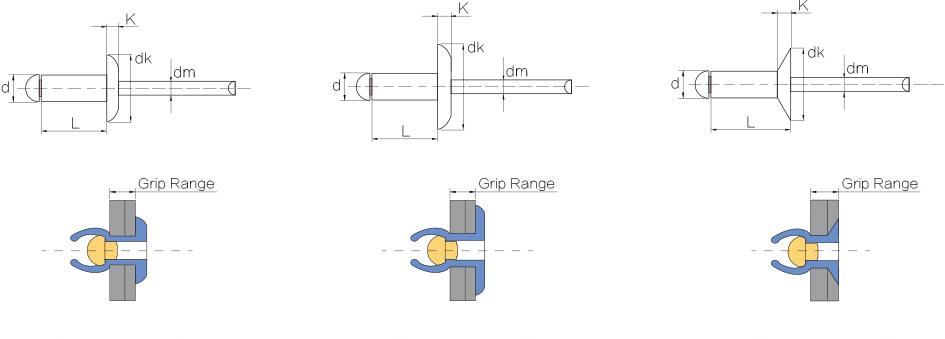

| Kalite tèt | Dome, CSK, gwo bride | |||

Spesifikasyon

| D1 NOM. | Egzèsis NO. & GWO TROU | ART.CODE | GRIP RANJE | L(MAX) | D NOM. | K MAX. | P MIN. | TAYE LBS | TENSILE LBS | ||

| POUS | MM | POUS | MM | ||||||||

| 3/32" 2.4mm | #41 2.5-2.6 | AA32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188" 4.8 | 0.032" 0.81 | 1.00" 25.4 | 70 310N | 80 360 N |

| AA34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| AA36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3.2mm | #30 3.3-3.4 | AA41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250" 6.4 | 0.040" 1.02 | 1.06" 27 | 120 530 N | 150 670 N |

| AA42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| AA43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| AA44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| AA45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| AA46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| AA48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| AA410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0mm | #20 4.1-4.2 | AA52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.312" 7.9 | 0.050" 1.27 | 1.06" 27 | 190 850 N | 230 1020 N |

| AA53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| AA54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| AA56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| AA58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| AA510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| AA516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | AA62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375" 9.5 | 0.060" 1.52 | 1.06" 27 | 260 1160 N | 320 1430 N |

| AA63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| AA64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| AA66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| AA68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| AA610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| AA612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| AA614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| AA616 | 0.875-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| AA618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| AA620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4mm | F 6.5-6.6 | AA82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0.080" 2.03 | 1.25" 32 | 460 2050 N | 560 2500N |

| AA84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| AA86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| AA88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| AA810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| AA812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| AA814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| AA816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| AA818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Aplikasyon

Rivet plen aliminyòm ouvè nou an sèvi ak bon jan kalite fil alyaj aliminyòm.Apre riveting la, Li p'ap janm rouye.konpare ak rive òdinè, entansite rivet la ba, kidonk li se apwopriye pou konekte materyèl la mou.Aliminyòm pòp rivet ka divize an yon rivet tèt bòl, rivet countersunk ak gwo rivet tèt bride.Ak materyèl la alyaj aliminyòm gen plizyè chwa nan alu mg 2% 2.5% 3.5% ak 5%(5052 5154 5056).

Fixpal louvri tip pòp rivet gen avantaj ki genyen nan operasyon fasil, ekselan riveting, bèl aparans, segondè pwopriyete fizik.Pafè chwa nan yon sèl-sided riveting.Aliminyòm pòp rivet ka lajman itilize nan machin divès kalite, veso, fabrikasyon machin, elektwonik, instrumentation, machin manje, ekipman medikal, konstriksyon, dekorasyon ak lòt zòn fixation.

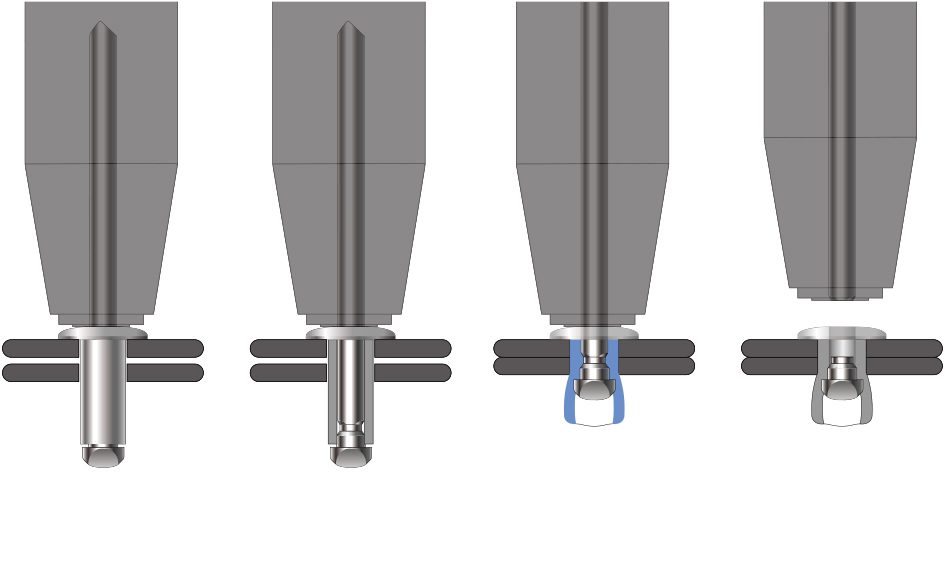

Pwoblèm ak rezon lè w ap itilize rivet avèg la:

1. Burrs: Apre riveting, mandrin kase a ak burrs pase nan twou yo rivet;oswa twou yo riveting soti deyò pou fòme yon burr spatul.

Kòz burrs yo: dyamèt mandrin lan piti;materyèl la rivet se mou;dyamèt twou perçage nan materyo a twò gwo;espesifikasyon mizo zam rivet yo twò gwo;

2. Tèt klou a tonbe: Apre yo fin rale rivet la, tèt nwayo a rivet pa ka vlope epi li tonbe soti nan rivet la.

Rezon ki fè yo tonbe tèt la rivet nan nwayo a se: dyamèt bouchon klou a twò gwo;Rivet la pi kout, epi epesè rivet la pa matche.

3. a rivet fann: Apre riveting la, rivet la enpulsyonèl oswa konplètman rupture.

Rezon ki fè yo fann nan rivet la se: twòp dite apre riveting annealing oswa tretman san chofe, chapo nwayo klou a twò gwo.