Materyèl

| Kò | Steel |

| Fini | Zenk plake |

| Mandrin | Steel |

| Fini | Zenk plake |

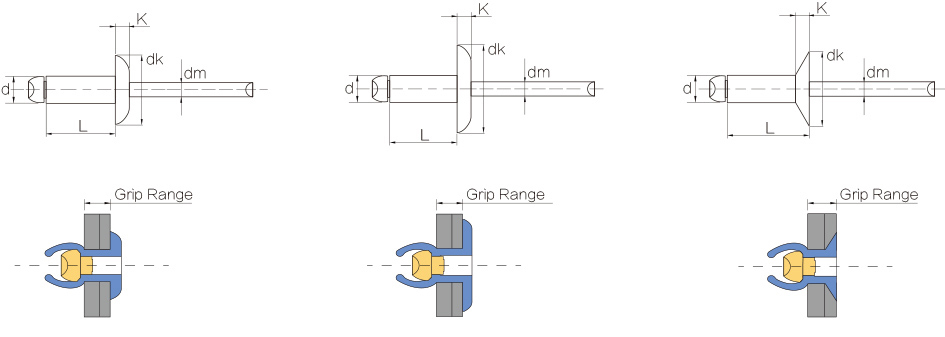

| Kalite tèt | Dome, CSK, gwo bride |

Spesifikasyon

| D1 NOM. | Egzèsis NO. & GWO TROU | ART.CODE | GRIP RANJE | L(MAX) | D NOM. | K MAX. | P MIN. | TAYE LBS | TENSILE LBS | ||

| POUS | MM | POUS | MM | ||||||||

| 3/32" 2.4mm | #41 2.5-2.6 | SS32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188" 4.8 | 0.032" 0.81 | 1.00" 25.4 | 130 580N | 170 760N |

| SS34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| SS36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3.2mm | #30 3.3-3.4 | SS41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250" 6.4 | 0.040" 1.02 | 1.06" 27 | 260 1160N | 310 1380N |

| SS42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| SS43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| SS44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| SS45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| SS46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| SS48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| SS410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0mm | #20 4.1-4.2 | SS52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.312" 7.9 | 0.050" 1.27 | 1.06" 27 | 370 1650N | 470 2100N |

| SS53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| SS54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| SS56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| SS58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| SS510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| SS516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | SS62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375" 9.5 | 0.060" 1.52 | 1.06" 27 | 540 2400N | 680 3030N |

| SS63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| SS64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| SS66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| SS68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| SS610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| SS612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| SS614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| SS616 | 0.876-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| SS618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| SS620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4mm | F 6.5-6.6 | SS82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0.080" 2.03 | 1.25" 32 | 1000 4450N | 1240 5520N |

| SS84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| SS86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| SS88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| SS810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| SS812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| SS814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| SS816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| SS818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Aplikasyon

asye rive louvri fen avèg pa sèlman fasilite yo sèvi ak, efikasite segondè, bri ki ba, ka diminye entansite travayè ak lòt karakteristik, men tou, koneksyon sere.Rivet asye yo ka divize an yon rivet tèt bòl, rivet countersunk ak gwo rivet tèt bride.Fòs rupture ak taye nan rive asye avèg yo pi wo pase rive estanda aliminyòm.Li se lajman ki itilize nan endistriyèl, ka satisfè bezwen yo nan demann fòs segondè.

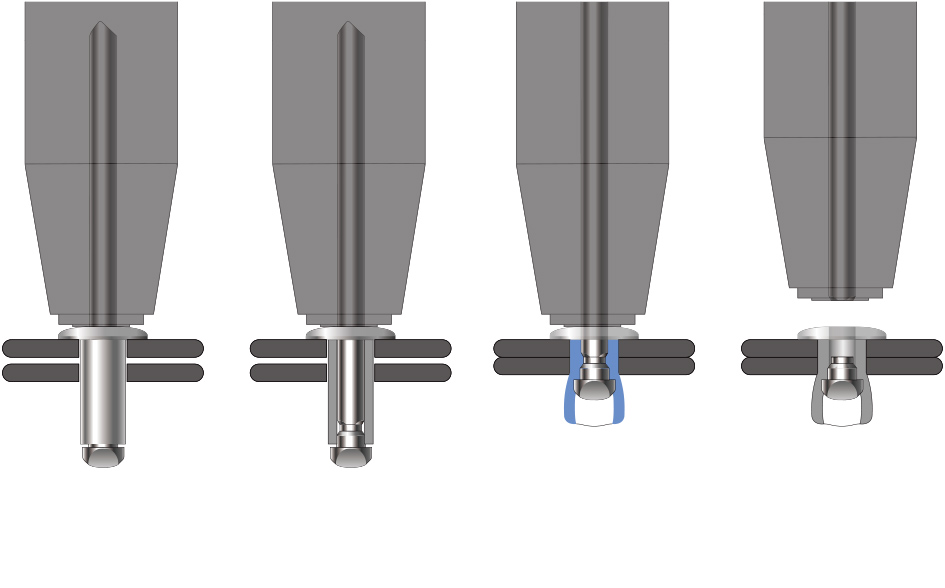

Pwoblèm ak rezon lè w ap itilize rivet pòp la:

4.Pop rivet la rale nan: mandrin rivet la konplètman rale soti nan rivet la, epi mandrin an kase.Apre riveting la, kite twou vid nan rivet la.

Rezon ki fè yo rale nan yo se: twòp tansyon mandrin rivet;ti dyamèt bouchon mandrin;materyèl mou riveting;sifas twou enteryè a twò grese.

5.Jump tèt oswa tanbou ensifizan: Lè w ap rale rive, nwayo a rivet parèt nèt, oswa rivet la pa anfle.

Rezon ki fè fenomèn sa a se: kontwòl fòs rupture a twò ba lè nwayo klou a fèt;kò a riveting se wo (rekwit inegal);

6. Rilaks apre riveting: Apre riveting, kò a riveting se ki lach nan twou a materyo.